7/16" 150' White Teufelberger KMIII Rope

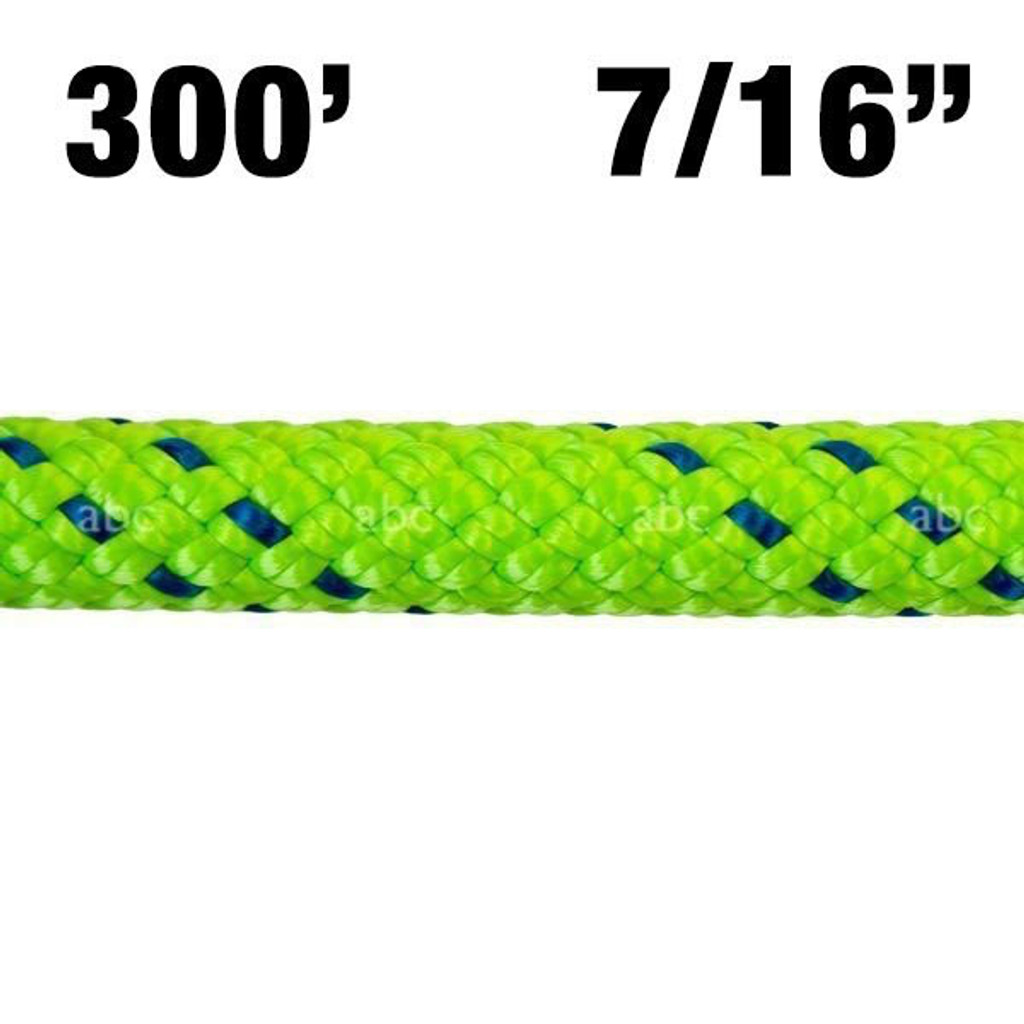

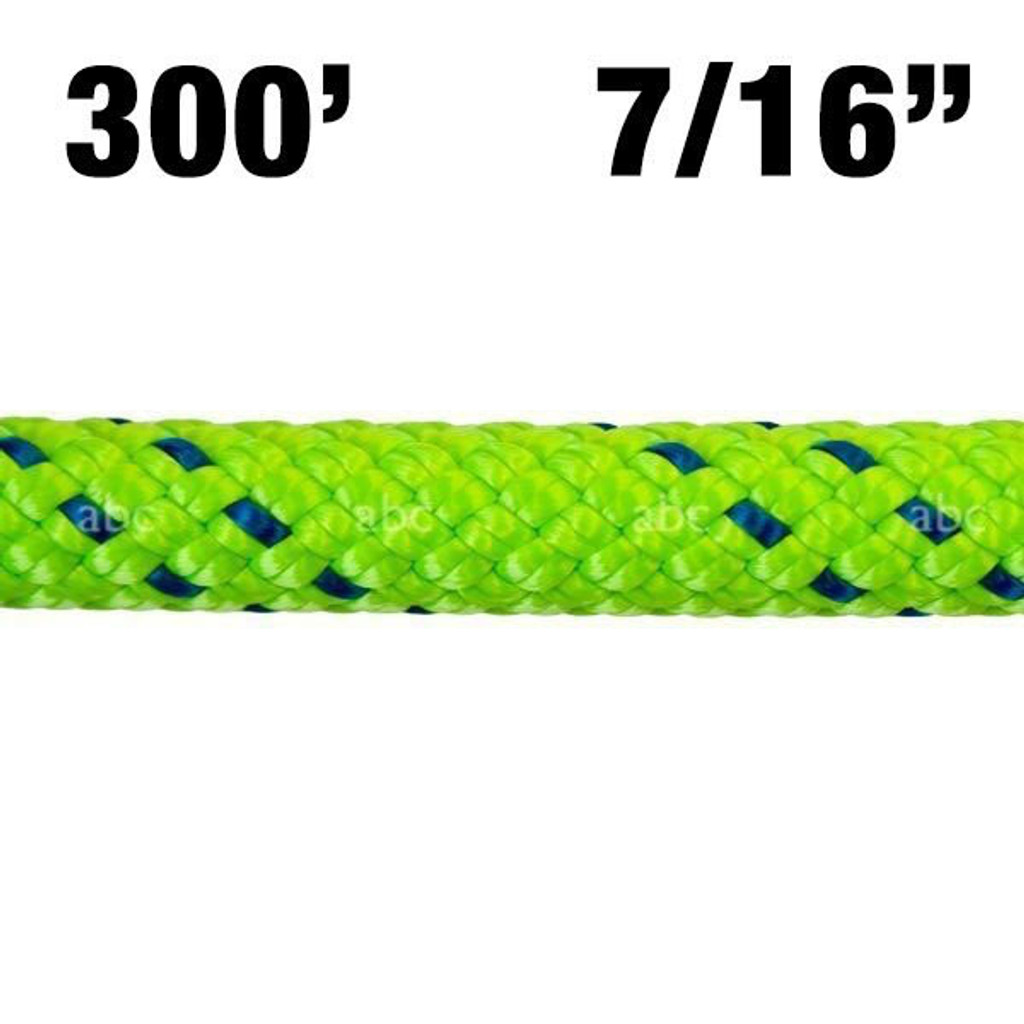

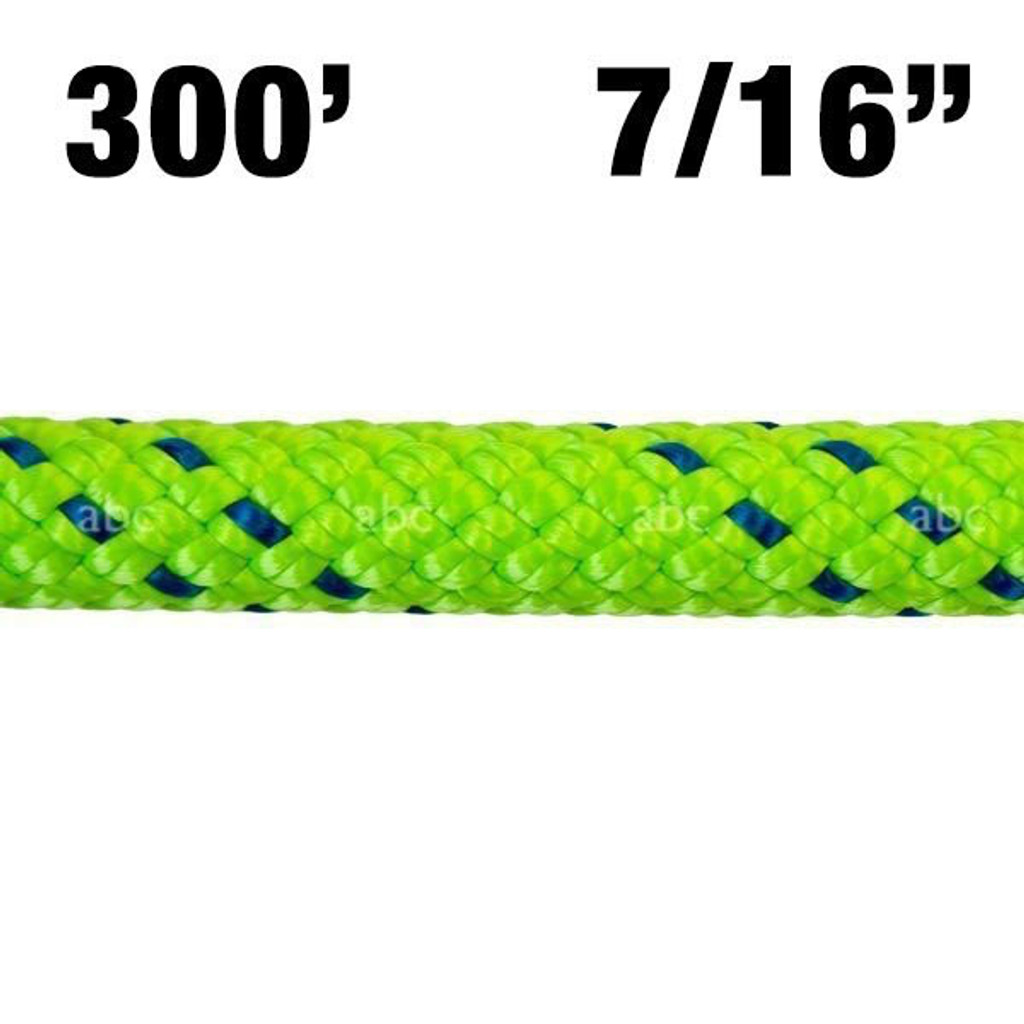

7/16" 300' Teufelberger KMIII Rope

7/16" 150' White Teufelberger KMIII Rope

7/16" 300' Teufelberger KMIII Rope

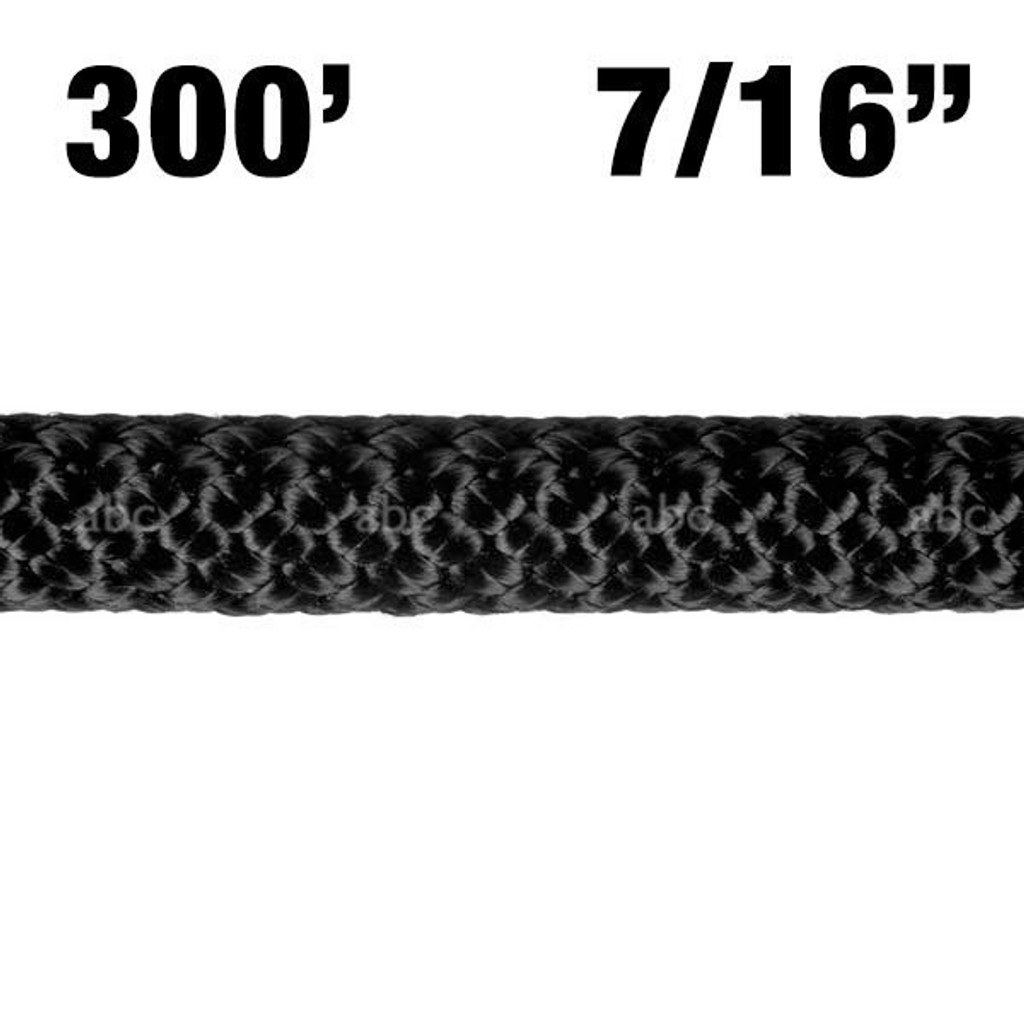

7/16" 400' Black Teufelberger KMIII Max Rope

7/16" 1,200' Teufelberger KMIII Rope

7/16" 600' Teufelberger KMIII Rope

7/16" 150' White Teufelberger KMIII Rope

7/16" 300' Teufelberger KMIII Rope

7/16" 400' Black Teufelberger KMIII Max Rope

7/16" 150' White Teufelberger KMIII Rope

7/16" 300' Teufelberger KMIII Rope

Description

KMIII static rope is a balanced construction consisting of a continuous filament polyester cover braided over a unidirectional nylon core. KMIII is designed to meet the rigorous requirements associated with rescue and rappelling operations. KMIII is dual certified (CE & NFPA). This rope was previously called New England KMIII. Teufelberger is the parent company of New England.

|

Available Colors

|

|

The polyester cover is very flexible, absorbs less water, has lower stretch, and is more abrasion resistant than the nylon covers found on some static ropes. The polyester cover and nylon core are balanced during manufacturing to attain the ultimate in performance.

|

|

KMIII static rope is a balanced construction consisting of a continuous filament polyester cover braided over a unidirectional nylon core. KMIII is designed to meet the rigorous requirements associated with rescue and rappelling operations. KMIII is dual certified (CE & NFPA).

|

|

Working Loads:

No blanket safe working load (SWL) recommendations can be made for any line because SWL’s must be calculated based on application, conditions of use, and potential danger to personnel among other considerations. It is recommended that the end user establish working loads and safety factors based on best practices established by the end user’s industry; by professional judgment and personal experience; and after thorough assessment of all risks. The SWL is a guideline for the use of a rope in good condition for non-critical applications and should be reduced where life, limb, or valuable property is involved, or in cases of exceptional service such as shock loading, sustained loading, severe vibration, etc. The Cordage Institute specifies that the SWL of a rope shall be determined by dividing the Minimum Tensile Strength of the rope by a safety factor. The safety factor ranges from 5 to 12 for non-critical uses and is typically set at 15 for life lines.

| Technical Specifications: | Sunlight/UV: | Chemicals: | Heat: | Dielectrics: | Sheaves: |

|---|---|---|---|---|---|

| 7/16" 400' New England Rope | Very little degradation from UV, and can be used over long term if inspected regularly. | Polyester has good resistance to most chemicals, except 95% sulfric acid and strong alkalis at boil. Nylon will degrade with strong oxidizing agents, mineral acids, and 90% formic acid. Nylon may discolor when exposed to high levels of carbon dioxide. | Polyester has a melting point of 480˚F with progressive strength loss above temperatures of 300˚F. Nylon has a melting point of 460˚F with progressive strength loss above 300˚F. | Good resistance to the passage of electrical current. However, dirt, surface contaminants, water entrapment, and the like can significantly affect dielectric properties. Extreme caution should be exercised any time a rope is in the proximity of live circuits. | Recommended D/d* ratio is 8:1. (*Sheave diameter to rope diameter) |

Customer Reviews

Be the first to review this product.

Add a Review

Account

Log in

New Customer

Create an account with us and you'll be able to:

- Check out faster

- Save multiple shipping addresses

- Access your order history

- Track new orders

Forgot Password

Forgot Password

Fill in your email below to request a new password. An email will be sent to the address below containing a link to verify your email address.